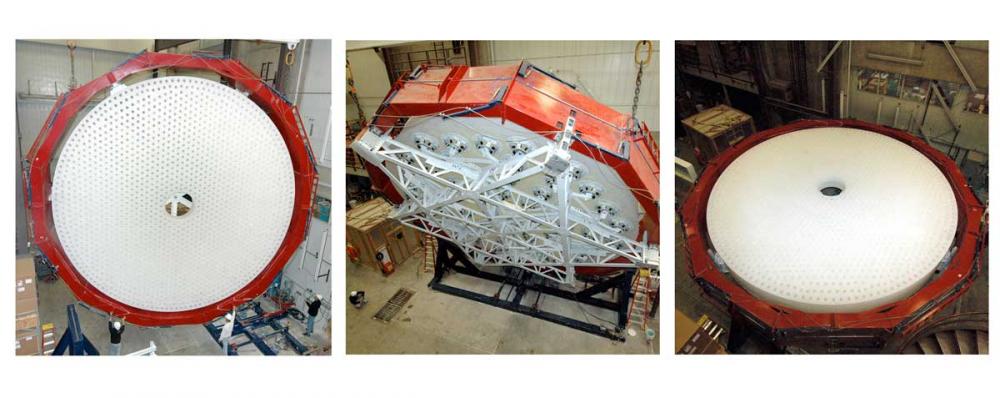

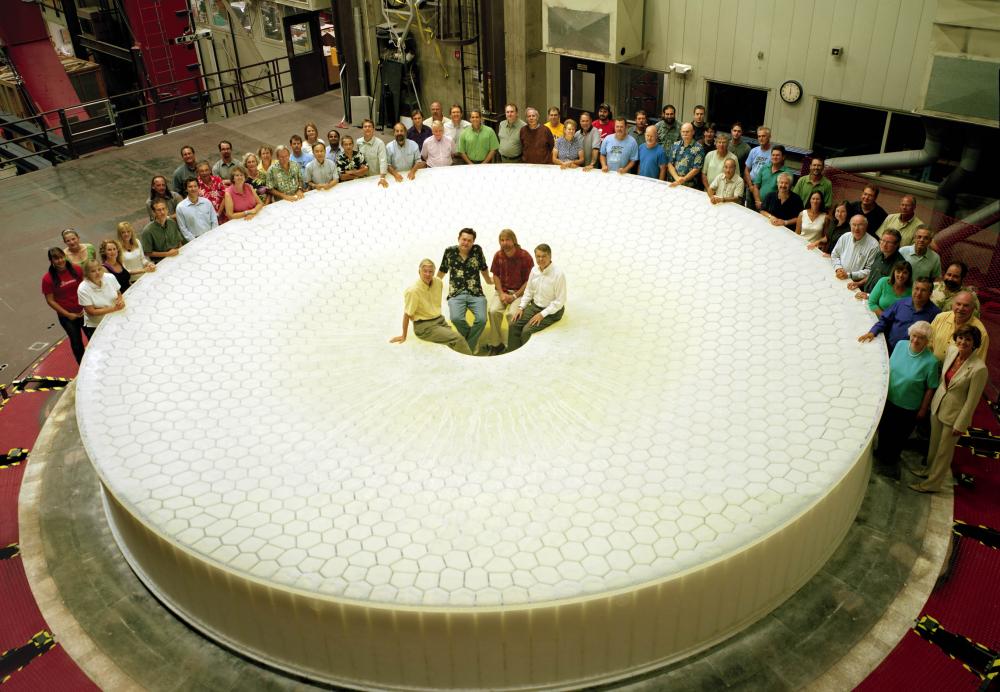

The LSST 8.4-meter mirror blank executed a couple of carefully choreographed turns and now rests horizontally in the large optical grinding area of the Steward Observatory Mirror Lab. Since October, when the mirror was lifted from the furnace hearth and installed vertically in the red handling ring, 16,000 kg of ceramic core material have been removed from the honeycomb structure. On the morning of January 13th, the 8.4-meter M1/M3 blank was moved forward, rotated vertically, moved back, and then carefully tilted so the back plate is now facing up; the face plate (with bonding pads still attached) lies on the underside of the horizontal glass monolith. In the large optics polishing area of the lab, the back plate and edges of the mirror blank will be ground down and polished in preparation for the next step - installation of load spreaders to the back plate. The mirror blank will then be placed in the polishing cell (with the face-plate up) before the multi-year polishing of the optical surface begins. The mirror is scheduled to be completed in January 2012, and will be the largest two-surface optical mirror ever made from a single substrate.