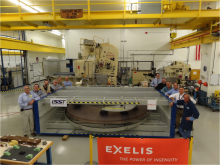

Clearly visible in this mid-June 2012 photograph are the dual optical surfaces in the LSST M1/M3 mirror blank. The steeper 5.0-meter diameter M3 surface, with its short radius of curvature, descends toward the center while the outer 8.4-meter diameter M1 surface sweeps outward to the edge of the substrate. Generation of both the M1 and M3 figure is now completed, with nearly 5 tons of glass removed to achieve the required approximate shape before polishing can begin. Laser tracker measurements confirm that the primary and tertiary surfaces are located properly with respect to each other. Next polishing actuators and thermocouples will be installed on the polishing cell for precision polishing of the front surface. The M1/M3 dual surfaces are scheduled to be complete in January 2012. Shown L-R: S. Jacoby, C. Claver, S. Wolff, V. Krabbendam, J. Schaefer.

Credit:

E. Acosta / LSST Corporation